ai PREDICTIVE MAINTENANCE

At ADC Energy, we apply advanced machine learning and domain expertise to deliver predictive maintenance for rig and vessel equipment. Our technology detects early signs of equipment degradation, optimises maintenance planning, and reduces unplanned downtime – improving safety, reliability, and performance.

Our AI doesn’t just analyse data – it understands your operations.

With decades of equipment maintenance and operational experience, we apply deep industry knowledge to every step of AI development. This allows us to extract meaningful insights from complex data, empowering engineers and decision makers to act with confidence.

“Our approach to technology development starts with understanding the real challenges our clients face, drawing from decades of experience in rig and vessel maintenance and operations. By combining this deep knowledge with data science, we’re not just solving today’s problems we’re shaping the future of the offshore sector.”

CRAIG DUNCAN, COMMERCIAL Director – INNOVATION

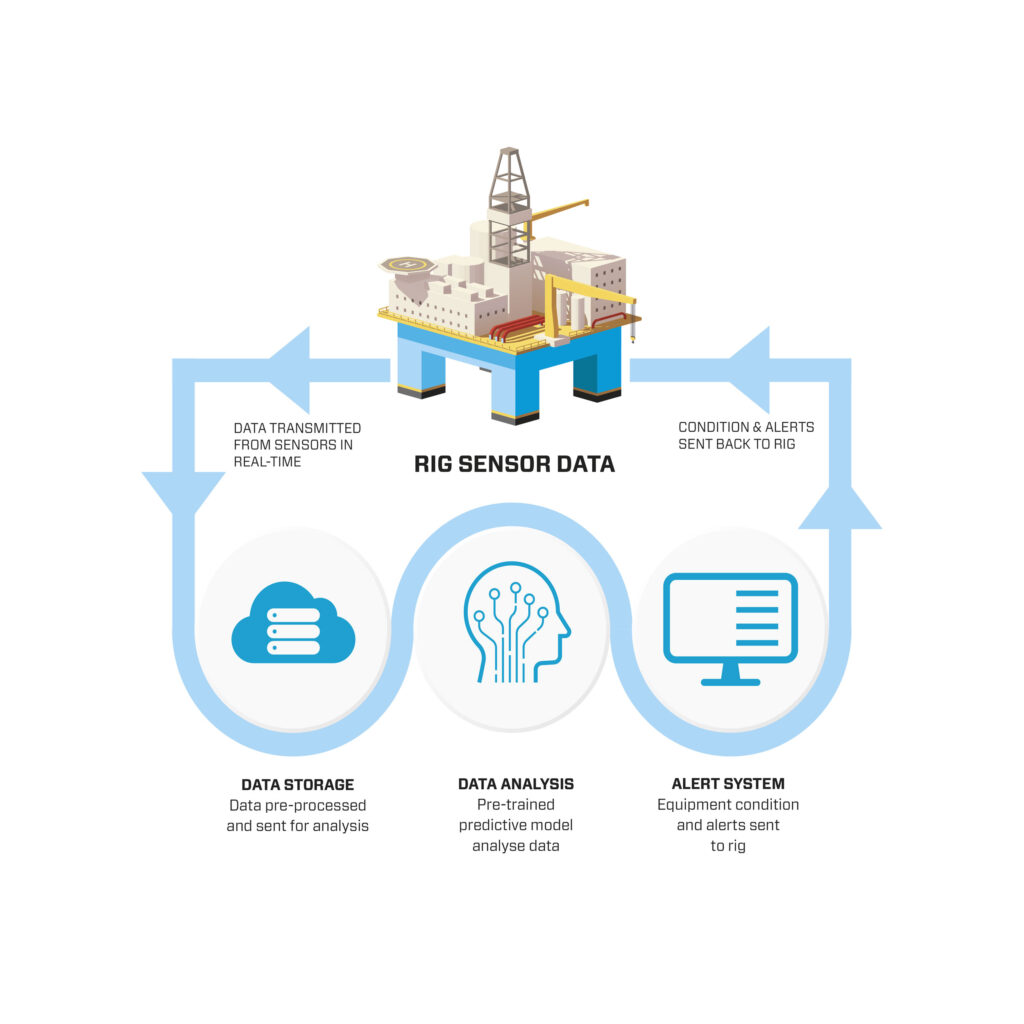

We deploy data collection systems on offshore rigs and vessels to unify disparate data sources, securely store the information, and build advanced predictive maintenance models.

Our solutions deliver clear, impactful visualisations that enable faster, smarter decision-making – helping operators reduce unplanned downtime and optimise maintenance strategies with confidence.

By combining domain expertise, data science, and Rig Owner datasets, our AI-driven tool predicts the remaining usable life of BOP elastomers with precision.

The impact? Optimised operational planning, extended maintenance intervals, and more operational days – driven by data-led decisions.

We deliver predictive maintenance solutions for high-value, safety-critical systems on rigs and vessels including:

Our expertise helps our clients detect early signs of failure, extend asset life, and ensure safer, cleaner and more efficient operations.

E: Email ADC UK