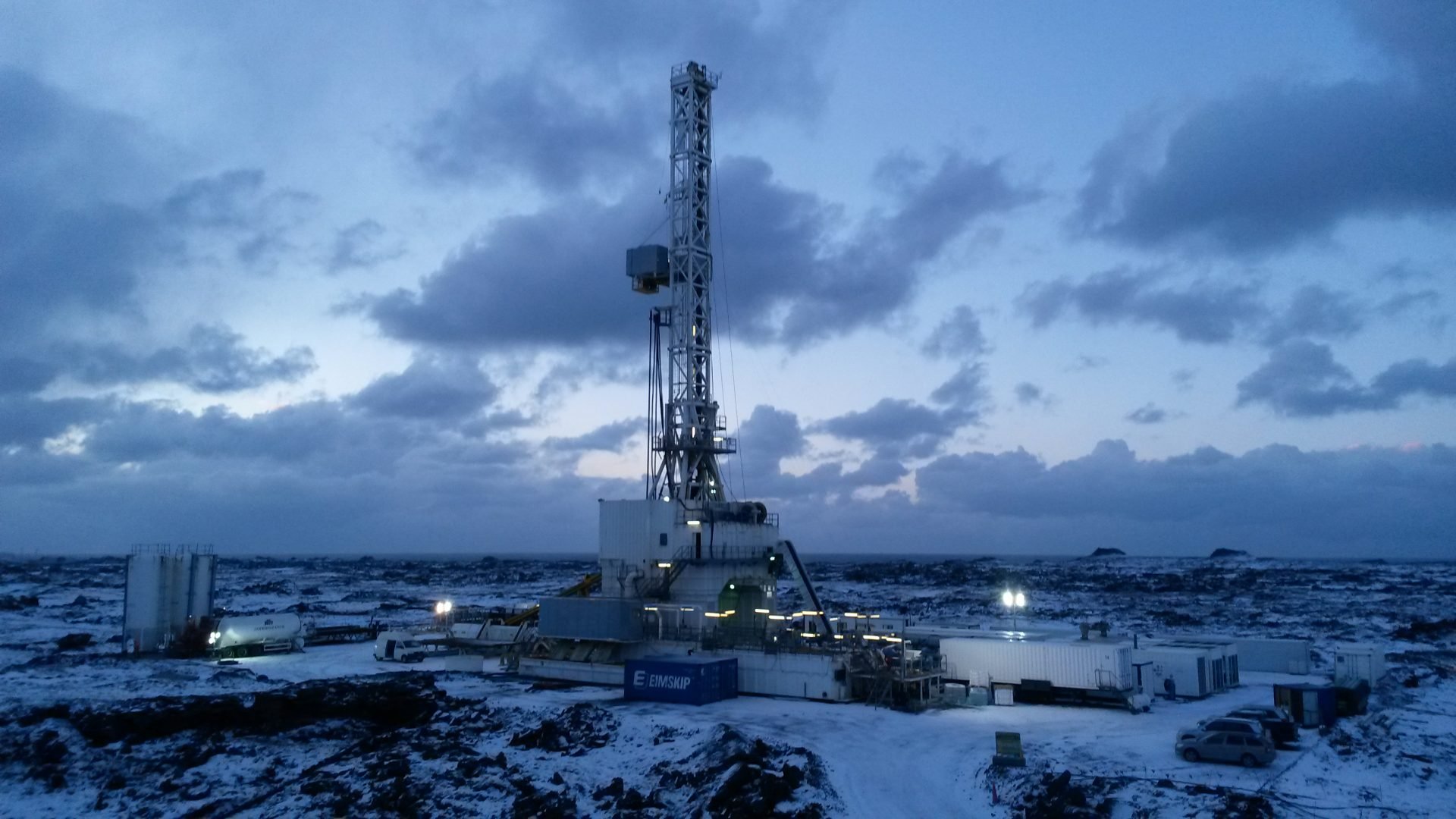

Geothermal DRILLING – RIG Inspection

Over the past decade we have undertaken several Geothermal rig assurance projects in diverse locations such as Iceland and Indonesia. Our objective is to help Energy companies ensure the rigs they are hiring are capable of performing their drilling operation efficiently and above all safely and with environmental integrity.

Our assurance scope covers the full rig intake process. In brief this entails initial desktop screening of suitable candidate rigs through to condition inspection and verification of acceptance testing to confirm the rig is operationally ready to drill. Moreover we tailor our scope to the specific operational requirements of the geothermal well our client is drilling.

The aim of the rig selection survey is to verify if the selected rig(s) are suitable for proposed operations and activities. Generally the focus is on the rig capability and availability of necessary drilling equipment, including certification.

And/or

Our rig condition and acceptance inspections aim to contribute to preparing the rig for drilling operations. In order to do this effectively we understand the importance of integrating with the rig crew and management. As a result we can give direct feedback enabling early rectification and closure of any non-conformances identified.

As with any ADC inspection we use the analysis of past inspection data to target known high risk areas based on identified common problem trends. Past analysis has identified trends across metrics such as rig designs, Rig Owners / Drilling Contractors, OEMs and operating locations.

All Non-conformances raised by ADC reference applicable standards including API and OEM functional design specifications. This approach is commended by both our ‘end user’ clients and the asset owners we audit. With this in mind ADC actively avoid “opinion-based” inspection, which is common place in the Industry, as it can lead to confusion and an inefficient inspection process.

E: Email ADC UK