The oil and gas industry has faced rising pressure to demonstrate decarbonisation efforts, and following COP26 and the subsequent Glasgow Pact, the world remains more focused than ever on reducing carbon emissions to reach net zero targets.

To support this drive, operators are increasingly re-evaluating existing assets to determine where energy efficiencies can be gained, and a key element of this process is the assessment of power management systems.

Dynamically Positioned (DP) rigs are widely used in deep water oil and gas exploration as they allow the asset to retain position over the wellhead using propellers and thrusters.

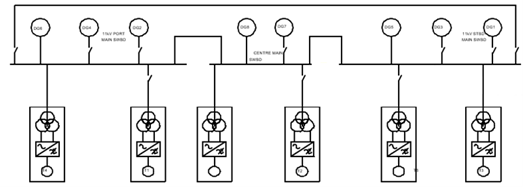

Generally, DP drilling rigs operate in a split-bus or open-bus configuration, with the power management switchboards operating as silos. A typical configuration will have all the breakers between the switchboards with each operating independently. This is the most fault-tolerant option to ensure malfunctions on one switchboard are not automatically transferred between the systems. While a split-bus configuration delivers greater asset assurance, it results in more engines being online than may be required for the total operational loads. Therefore, the engines are not working as efficiently as intended and can create greater emission output. As rig owners strive to reduce fuel consumption, this option is no longer viewed as the ideal mode of power management.

The application of closed-bus operations is not a new concept. However, as the industry continues to focus on decarbonising existing assets, there has been a greater emphasis on how rigs can successfully transition to this configuration to deliver a more efficient power management system.

When operating in closed-bus mode, the switchboards are tied together, enabling the power plant to run with fewer engines and more optimal loads, resulting in a significant reduction in fuel usage.

While this option provides a more efficient power source, it does present assurance threats. With switchboards operating together, and not independently, faults can more easily transfer from one engine room to another. In worst-case scenarios, this can result in a total blackout of the rig. While there is a clear desire from operators to drive energy efficiency goals, operational integrity must be guaranteed throughout this process. Therefore, investment in technology is essential to allow this change to happen safely and efficiently.

ADC Energy recently completed a project with a major rig owner to analyse a rig’s current power management system and determine if it could safely and effectively operate in a closed-bus configuration.

As part of the project, Failure Mode and Effects Analysis (FMEA) was conducted to determine if the existing protection system was able to support this transition. As asset assurance is an integral element to consider when evaluating power management systems, it is critical that testing parameters are analysed to mitigate any risk to the rig.

The project highlighted that moving to closed-bus mode could successfully reduce annual CO2 emissions by 4,800 tonnes per year – potentially delivering a fuel saving of $620,000 per year – while reducing engine running hours by 20%.

With the number of engines required to be online at any given time decreased, the enhancement also provides operators and asset owners with greater maintenance schedule flexibility, which can create potential savings of up to $150,000 per annum. The project clearly demonstrates how operators can utilise specialist inspection providers to help navigate them through this process to ensure that assets continue to operate securely and efficiently with minimal environmental impact.

Existing assets will play a key role in the energy transition, but rig owners currently face a difficult balance of reducing carbon emissions, while recovering from the effects of the Covid-19 pandemic. For the industry to achieve its goal of decarbonising assets and deliver more sustainable operations, investment is critical. While we are seeing encouraging signs of this, the industry must act quickly if we are we are to move towards a net zero future.

E: Email ADC UK