In February 2017, following recent bolt failures experienced with both Vetco H4 and Cameron Collet connectors, attributed to hydrogen embrittlement of H4 connector bolts, API released a new bolting specification – API Spec 20E for carbon steel (Available to Purchase from API). An earlier version of API Spec 20F – Corrosion Resistant Bolting for Use in Petroleum & Natural Gas Industries, included specifications for stainless steel bolting.

This new specification, API Spec 20E, outlined the material specifications for 3 different levels of bolting. The new specifications are detailed and go extensively into the metallurgy of the bolts, including grain structure requirements post heat treatment.

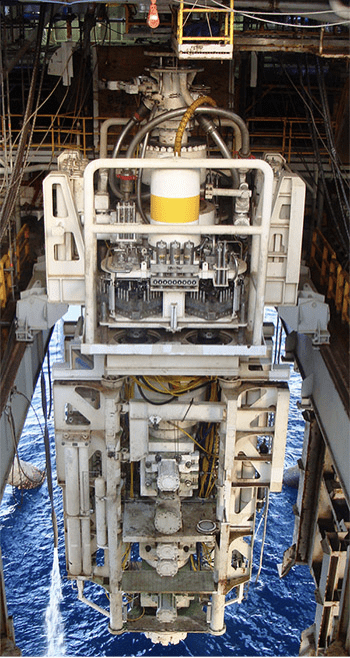

A BOP is a large set of specialised valves used for controlling and monitoing an oil or gas well. Want to know more? ADCs Virtual Academy can provide training worldwide 24/7 on Drilling Equipment, IWCF level 2 Well Control, and Understanding Dropped Objects. Click here to find out more

The main points which arise from this revision are that the fasteners used in BOP flanges (B7, L7, L44 etc.) have to conform to 3 Bolting Specification Levels – BSL’s (BSL-1, BSL-2 & BSL-3) and to meet API 20E or 20F, have to be stamped with 20E1 for BSL-1, 20E2 for BSL-2 or 20E3 for BSL-3 in addition to the already required B7, L7, L44 grade stamp and a unique heat code stamp is also a requirement.

The latest edition of API Spec 16A (Available to Purchase from API) is the 4th edition (effective date 01 February 2018), inclusive of the Errata 1 – date of issue: August 2017. This revision of API 16A (with the inclusion of Errata 1) included a change to the effective date of the Specification from the 1st October 2017 to 1st February 2018.

It is understood that this extension, given from October 2017 to February 2018, was to allow for contractor compliance, however they would have to be fully compliant by February 2018.

API Spec 20E and 20F are international specifications / standards and are stated as normative references within the fourth edition of API Spec 16A.

API 16A, Edition 4 released in April 2017 became effective as of the 1st October 2017 and this states what BSL the bolts of certain equipment are required to be. This is laid out in Table 6 (on page 21) for Land and offshore service.

In accordance with the latest revisions of API Spec 16 A, 20 E & 20 F, pressure retaining and closure bolting needs to meet API 20E & 20F BSL-3 specifications (on surface and subsea BOP’s) and for land use, pressure retaining and closure bolting needs to meet API 20E & 20F BSL-2 specifications.

For API Spec 20E compliance bolting was to be marked as follows:

This will impact the vast majority of every bolt/stud used on the BOP for all flanges, hubs and bonnet closure.

Now that these changes to API have been in place for some time, current BOPs inspected are still being found non-compliant with these Specs and are therefore highlighted as a non-conformance against the appropriate API specifications at the conclusion of our rig and BOP inspections. There are a number of challenges faced by the industry as a whole including a shortage in supply of these bolts for the OEMs. It is the responsibility of the Drilling Contractor to put in place a Management of Change to mitigate the risk of failure and ensure an ongoing change out process.

| Material | Land(1) | Offshore(2) | ||

| Pressure-Controlling Bolting | Alloy Steel & Carbon Steel Stainless Steel & CRA | API 20E BSL-1(3) API 20F BSL-2 | API 20E BSL-2(3) API 20F BSL-2 | |

| Closure Bolting | Alloy Steel & Carbon Steel Stainless Steel & CRA | API 20E BSL-2(4) API 20F BSL-2 | API 20E BSL-3(4) API 20F BSL-3 | |

| Pressure-retaining Bolting | Alloy Steel & Carbon Steel Stainless Steel & CRA | API 20E BSL-2(4) API 20F BSL-2 | API 20E BSL-3(4) API 20F BSL-3 | |

| Utility Bolting | Alloy Steel & Carbon Steel Stainless Steel & CRA | Mfg. Spec. (4) Mfg. Spec. (4) | Mfg. Spec. (4) Mfg. Spec. (4) |

NOTE:

(1) General Requirements listed in 4, 3, 3, 1 apply to all bolting

(2) General requirements listed in 4, 3, 3, 2 apply to all bolting

(3) Need to conform to API 6A for material class and material testing

(4) Based on manufacturer’s written specidication

E: Email ADC UK