This is a question that is posed to ADC during every proposal stage of a reactivation project. The simple answer is that the overall cost will be a result of how efficient the reactivation plan proves to be. However, the effectiveness of the preservation methods can only be realised and assessed once you start to de-preserve the equipment and reboot the systems.

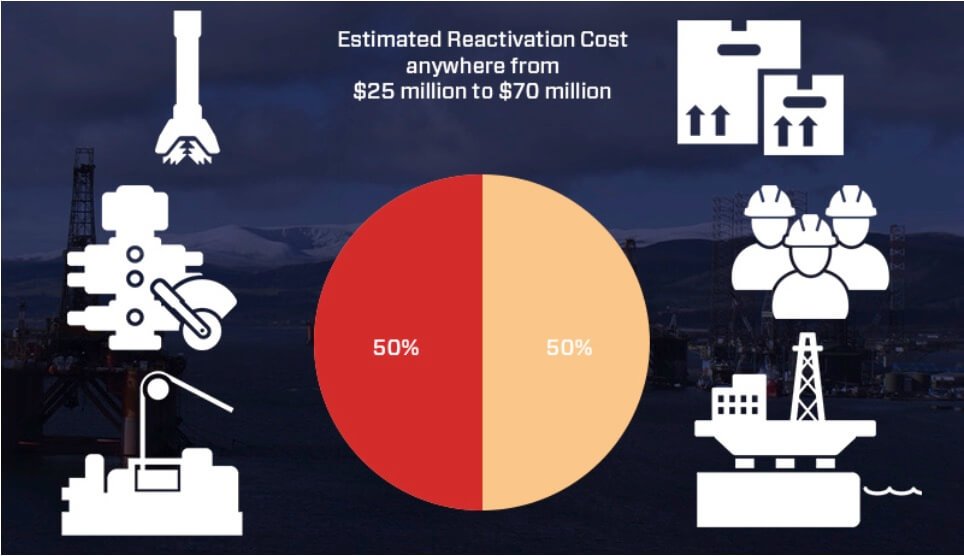

The estimated range for reactivation costs for cold-stacked floaters is anywhere from $25mil to $70mil with approx. 50% of the cost emanating from the commissioning of major equipment including de-preservation and reinstallation with ancillary services (crew, shipyard and logistics etc.) accounting for the remaining 50%. Inevitably, even with the best-laid plans, problems will occur and delays will be experienced so it is important to develop an integrated reactivation plan that considers everything from classification, crewing, compliance and operability assurance (incl. endurance testing).

With an increasing number of Operators discounting rigs that have been cold stacked for a period in excess of 18 months during rig selection tenders, it poses the question, “Is it worth it?”

ADC has had the benefit of being involved in reactivations with varying factors (i.e. rig status, logistical location, drilling contractor project execution, operational location and Operator requirements), which helps to implement a common factor during the reactivation plan. The experience of the Drilling Contractors reactivating the stacked fleet will improve with time and it’s important to appreciate lessons learned in order to continuously reduce the reactivation cost and make stacked rigs more of a viable option.

E: Email ADC UK